Following months of promising take a look at effects, battery researchers on the Division of Power’s Oak Ridge Nationwide Laboratory are recommending that the solid-state battery trade focal point on a method referred to as isostatic urgent because it seems to be to commercialize next-generation batteries.

Industrial-scale manufacturing of solid-state batteries is a purpose for electrical automobile producers as a result of those batteries have the possible to fee quicker, last more and function extra safely than the lithium-ion batteries lately in the marketplace.

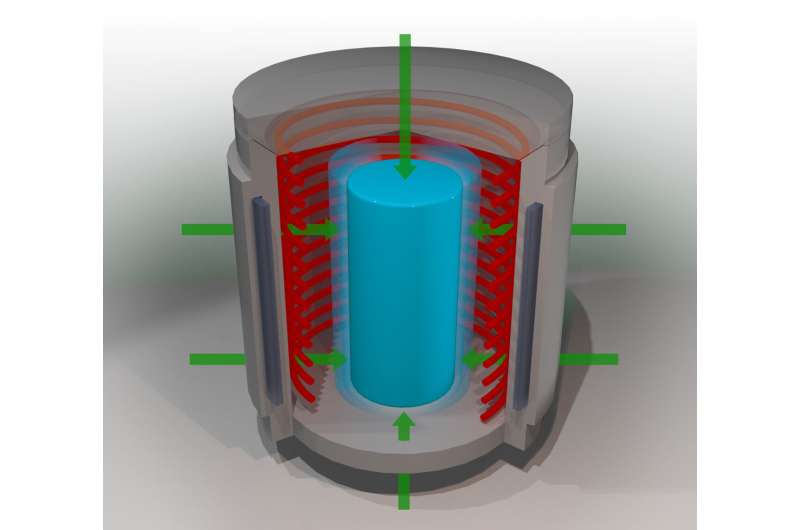

In a focal point assessment paper for ACS Power Letters, ORNL researchers suggest consideration be given to the little-studied isostatic urgent way. This procedure makes use of fluids and gases like water, oil or argon within a gadget to use constant force throughout a battery element, making a extremely uniform subject matter. With the assistance of an trade spouse that produces this urgent apparatus, ORNL researchers discovered that isostatic urgent may just make battery manufacturing more straightforward and quicker whilst developing higher prerequisites for calories glide.

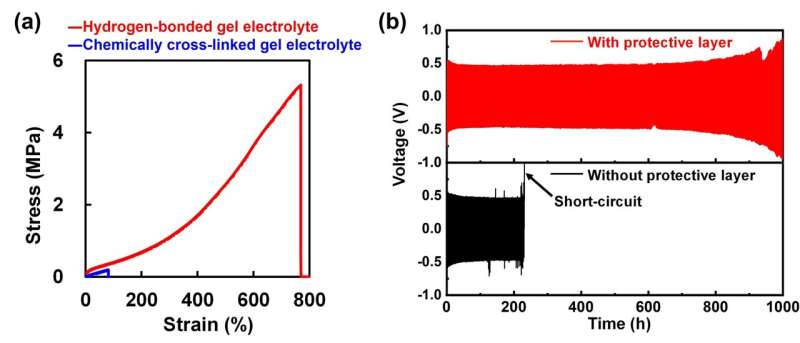

When a battery fees or discharges, ions transfer thru an electrolyte between its sure and unfavorable poles, which can be made of skinny layers of steel. Within the lithium-ion batteries that energy the whole lot from cellphones to electrical cars, the electrolyte is a liquid during which ions trip simply. Sadly, this liquid too can spill or ignite if the separation between battery layers is compromised.

ORNL’s Marm Dixit and associates discovered that isostatic urgent can create skinny layers of strong, uniform electrolyte, keeping up a prime stage of touch between the layers for clean ion motion. The process works with quite a few battery compositions at other temperatures and pressures.

Some of the promising effects, isostatic urgent used to be discovered to be extraordinarily a hit at low temperatures and with comfortable electrolyte fabrics, which can be more straightforward to procedure and that have favorable crystal buildings for ion motion. Up to now isostatic urgent of batteries were carried out most commonly at extremes: very prime temperatures or at room temperature, however no longer in between.

“These kind of fabrics have their distinctive benefits that researchers want to exploit,” Dixit mentioned. “That is why it can be crucial that you’ll do isostatic urgent at any place from room temperature to a number of thousand levels Fahrenheit: It way you’ll use anything else from polymers to oxides, the entire vary of fabrics.”

This versatility is essential to a constant production procedure for the wide number of solid-state battery designs and fabrics being advanced, Dixit mentioned. Isostatic urgent would even be somewhat simple to scale up commercially—a discovering that has garnered vital consideration as corporations race to provide solid-state batteries to automotive producers. A number of main auto corporations have introduced their purpose to promote electrical cars that run on solid-state batteries inside of a couple of years.

Ilias Belharouak, a company fellow at ORNL and head of its electrification segment, mentioned solid-state battery generation must be perfected for large-scale production. “Make no mistake, all solid-state batteries are on a adventure for the lengthy haul,” he mentioned. “However the isostatic urgent generation, if scalable, would offer a option to compile the battery layers with out impractical exterior pressures.”

Isostatic urgent has been used for many years in fusion bonding and becoming a member of fabrics. Not too long ago, it’s been a device for getting rid of voids and anomalies in Three-D-printed portions. Alternatively, its trying out for battery programs has been restricted.

ORNL researchers indicated isostatic urgent may additionally permit production the 3 battery layers as a unmarried, dense machine slightly than developing them one at a time prior to becoming a member of them.

Within the ACS Power Letters paper, Dixit’s workforce stressed out the significance of pursuing a solid-state battery that may be scaled up for production. “Successfully addressing this problem would leapfrog present-day battery generation into the following a long time through enabling energy-dense solid-state batteries to fulfill the burgeoning calls for of moveable electronics, grid garage, electrical cars or even (aviation) programs,” they wrote.

ORNL researchers are proceeding to behavior assessments to be informed which urgent temperature and force mixtures paintings easiest with other fabrics, and the way the ones elements impact texture. “Isostatic urgent can modify texture—the query is whether or not it will possibly actively keep an eye on it,” Dixit mentioned. “The power to control crystal texture would have vital advantages for solid-state batteries.”

Additional info:

Marm Dixit et al, The Position of Isostatic Urgent in Massive-Scale Manufacturing of Cast-State Batteries, ACS Power Letters (2022). DOI: 10.1021/acsenergylett.2c01936

Quotation:

Analysis workforce helps isostatic urgent for solid-state battery production (2023, March 23)

retrieved 25 March 2023

from https://techxplore.com/information/2023-03-team-isostatic-solid-state-battery.html

This file is topic to copyright. Aside from any honest dealing for the aim of personal learn about or analysis, no

phase is also reproduced with out the written permission. The content material is supplied for info functions best.

Supply By means of https://techxplore.com/information/2023-03-team-isostatic-solid-state-battery.html